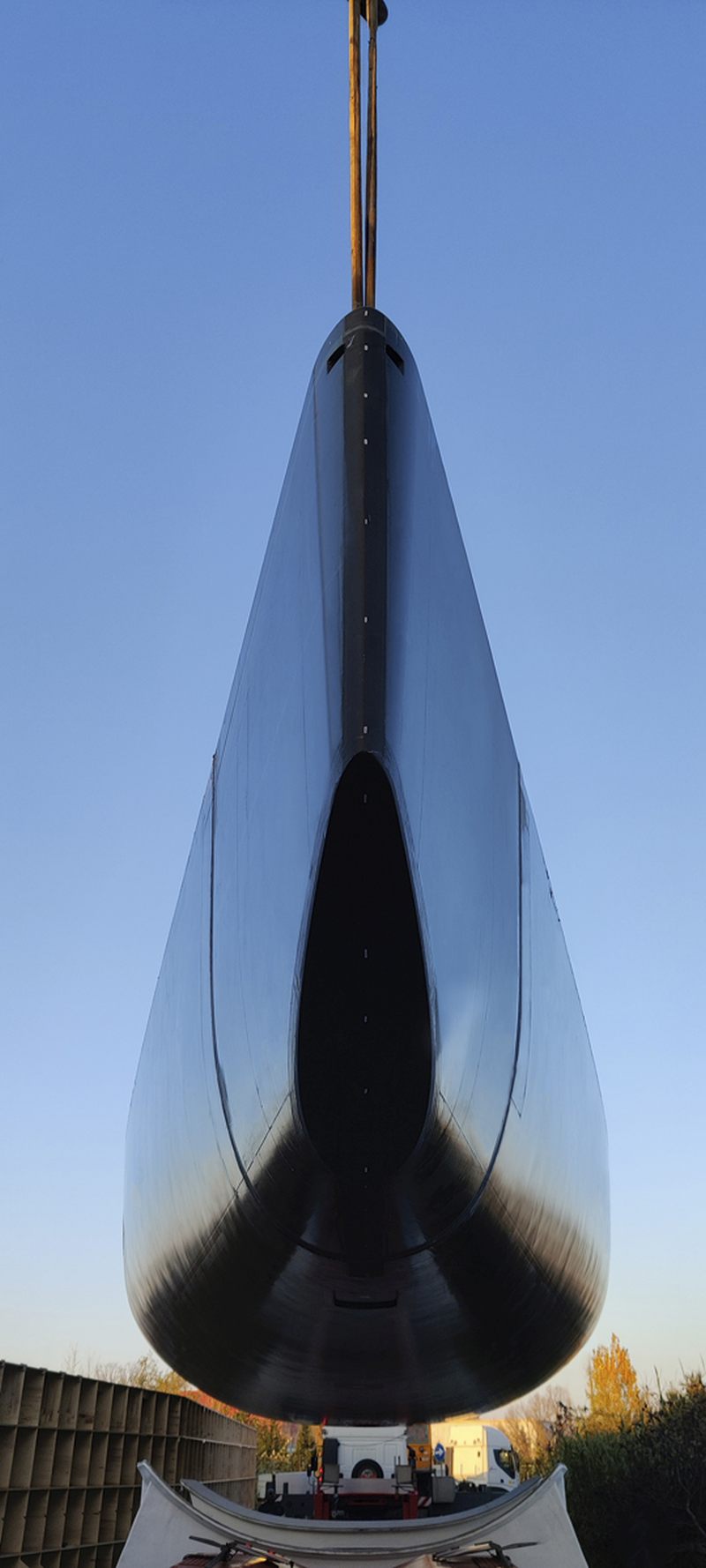

Wally’s latest bespoke sailing creation has just passed a crucial construction milestone with the demoulding of the hull.

The sleek carbon hull of the new 101-foot cruiser racer was lifted out of its female mould. She is the fourth Wally for an experienced owner and inspired by the Wallycento box rule.

It is rare for one-off yachts at this scale to use female moulding, which is time-consuming to build. But it was the right decision, because a female mould ensures a near perfect exterior finish. As a result, very little filler was needed to fair the hull, further eliminating unnecessary hull weight – a critical part of the owner’s brief.

It is still a heart-stopping moment in any big full-carbon boatbuilding project when the hull is revealed for the first time. The lines and exterior form are seen at last, and the quality of the construction is laid bare for all to see. Being a Wally, with minimal, flowing lines and easy power in its DNA, the new 101 was under intense scrutiny – something she bore with ease. The finish was perfect, thanks to the unmatched skills of the lamination team.

“This is the moment in the birth of a boat when her concept takes material shape for the first time and you get a glimpse of the vessel she will become. It is thrilling to watch,” says Wally Managing Director Stefano de Vivo. “In this case, her purposeful bow and powerful lines promise exhilarating performance and spellbinding looks.”

“Our laminators have been with Wally since the brand’s first days, and are among the best in the world. Their collaboration has helped us to develop techniques that bring the absolute best out of the high-end materials pioneered by Wally.” says Wally Founder and Chief Designer Luca Bassani. “We are invariably confident that all those hours of painstaking preparation and work pay off. We are delighted to be one step closer to welcoming a fabulous new custom Wally into the world.”

Built using advanced pre-preg carbon fibre in a sandwich composite, the Wally 101 weighs just 56 tonnes. That is some 20 per cent less than yachts of similar size and capabilities and comes in spite of a host of labour-saving technology. This includes Wally’s Magic Trim and Magic Traveller hydraulic systems. Astonishingly, 40 per cent of her weight is from the lifting keel alone, promising eye-watering performance.

After demoulding, the hull was laid in a cradle and moved back under cover for the next stage of its transformation. Shipwrights are already installing the bulkheads that will divide up the interior space, with wiring, piping, tanks and other engineering foundations while the lightweight carbon deck is currently in mould.