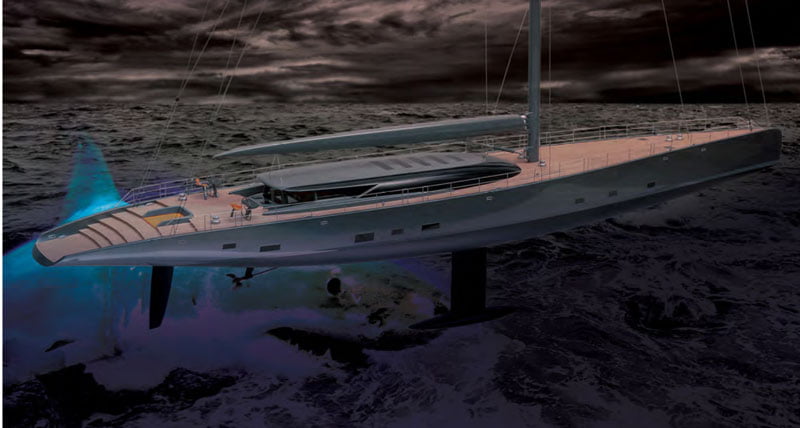

When the design and build team first announced this “edgy and innovative” project as “the Beast” during the 2014 Monaco Yacht Show, the yachting world pricked up its ears.

Now, nearly one year before delivery, this striking sloop designed by the late Ed Dubois (see sidebar) is taking a lion’s share of space at the shipyard. “Build me a beast. Don’t build me a wolf in sheep’s clothing. This has to be an edgy and innovative weapon; fast and furious,” was the owner’s instruction to Dubois and Royal Huisman. Working to this dramatic brief, Dubois designed a fast, ocean-going cruiser that is both excitingly different and luxuriously comfortable. And for Royal Huisman, their job is to ensure it is also beautifully built. With the aluminium work complete, the dramatically inflected sheer line, plumb bow and sculpted superstructure of this progressive design are now clearly visible with the project remaining on schedule for delivery in spring 2017.

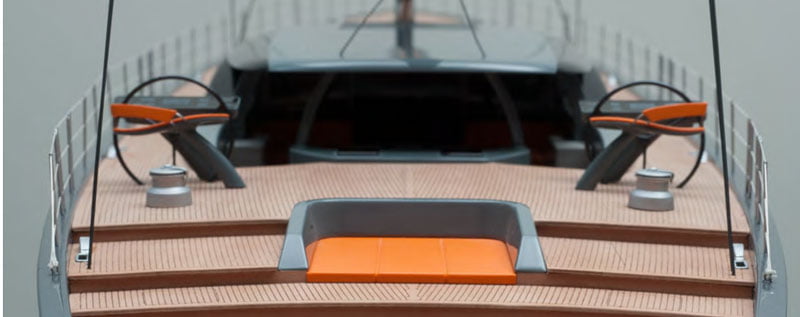

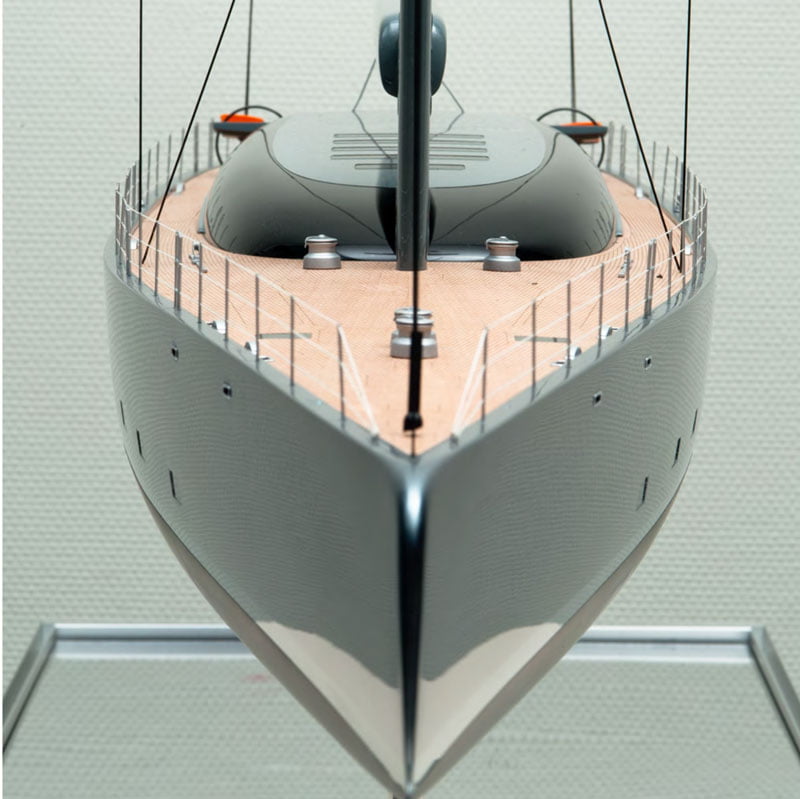

The bow section with its flush deck furlers is not just striking to look at, but has been proved in wind tunnel tests to create less wind disturbance to the leading edge of the headsail when compared to a conventional bow. The long and slender hull combined with a hugely powerful 71m / 234ft Rondal mast demanding high forestay tensions, requires all the stiffness that advanced engineering can mastermind. Not unexpectedly, a detailed Finite Element Analysis (FEA) of the structure as a whole revealed considerable compressive down forces.

The reverse inflection to the sheer alone has accounted for a 12 per cent increase in strength for an equal amount of material. This is especially relevant considering the large cut-outs in the foredeck for deck sail lockers, a tender garage, crane, spa pool and sealed waste locker, whilst below the waterline there are cut-outs for two submarine anchors and the fullyretractable bow thruster.

The innovations continue with the all carbon Rondal mast and “style to order” in-boom furler designed to carry a powerful square-head main by North Sails NZ. A special system has been devised whereby the top of the square-head main and its diagonal batten can be completely furled out of sight into the boom. A mainsail headboard lock alleviates compressive loads to the mast tube whilst halyard creep is completely negated at full hoist and reef points. The “style to order” performance boom is designed to complement the yacht’s exterior aesthetics that incorporates Rondal’s proprietary outhaul car that maintains the mainsails foot and leach tension at all hoist positions. Moreover, the boom’s open forward end means the furling process can be visually checked to keep the luff perfectly controlled. Computer simulations aside, a working test model complete with mainsail, mast section, and 7-metre boom has been built for continuous testing by Rondal’s R&D division.

Specifications

Naval architect: Dubois Naval Architects

Interior design: Rick Baker / Paul Morgan

Lighting design: The Light Corporation

Project management: Godfrey Cray Maritime Ltd

and Captain Iain Cook

Length: 58.15 m / 190 ft

Length waterline: 51.20 m / 168 ft

Beam: 9.54 m / 31 ft

Draft (keel up): 5.30 m / 17 ft

Draft (keel down): 8.10 m / 26 ft

Displacement: 342 tons / 754,740 lbs

Hull / superstructure: Alustar aluminium

Hull speed: 17.5 knots

In line with the performance parameters requested by the owner, the carbon fibre standing rigging by Carbo-Link provides some 70 per cent weight reduction over conventional Nitronic rod rigging. To further reduce weight and drag, the team opted for continuous shrouds from deck to masthead with internal connections where diagonal stays meet the mast tube. All in all, they provide less weight and drag, greater service life and fewer points of failure if compared to Nitronic.

Because the square-head main prevents the use of a fixed backstay, there are two running top stays with a deflector mechanism, as seen on grand prix racing yachts. And let’s not forget Ngoni’s lifting keel with its monolithic keel trunk milled from solid aluminium to support close to 100 tonnes of fin and lead bulb weight.

As an experienced yachtsman, the owner insisted that the steering should be light yet firm and responsive: “I want to get off the wheel after a day of sailing feeling completely knackered from the excitement of hands-on fast sailing.” As with all Huisman yachts there will be no hydraulic or electric power assisted steering but rather a well-balanced high-aspect carbon composite rudder controlled by a low friction system of chain, cables and linkages to provide the helmsperson the ultimate in sensory feedback.

Details of the interior styling by Rick Baker and Paul Morgan are currently restricted, but rest assured it will be every bit as bold and beautiful as the exterior styling. We can reveal that the lightweight interior will be based on fluid and organic “floating” forms featuring bespoke finishes.

With production well underway for the LY-3 approved crew quarters, the remaining accommodations comprise a master ‘apartment’ (including gym, steam room and book-lined study), two generous guest staterooms and a large open-plan deck salon extending to an al fresco seating and dining area on deck.

Like all Royal Huisman projects the Beast represents a custom set of challenges where the owner is driving the shipyard to achieve efficiency through simplicity. In the words of Godfrey Cray acting as the owner’s project manager: “He wanted a fast, uncomplicated and comfortable boat optimized for weight and performance that is going to make a statement—not a science project.”

Maximising reliability and reducing maintenance to a minimum requires balancing the needs of the client with those of the crew in order to operate the yacht efficiently and safely. To this end, the shipyard has worked closely with the owner’s team to evaluate where the systems architecture can be simplified. This involved, for example, looking at the alarm and monitoring system to minimise the number of sensors, thus eliminating the associated wiring and readouts. A case of ‘must have’ versus ‘nice to have’ has been the modus operendi. “When you look at our past projects it is very noticeable – aside of company standards – that none look or behave alike. Instead, they exemplify the nature of bespoke yacht building,” says Alice Huisman. “With her distinctive modern looks and high performance, Ngoni sends a clear message that she is no ordinary custom yacht, built by no ordinary custom shipyard.