When they’re not meeting challenges presented by the world’s most discerning clients, Feadship challenges itself.

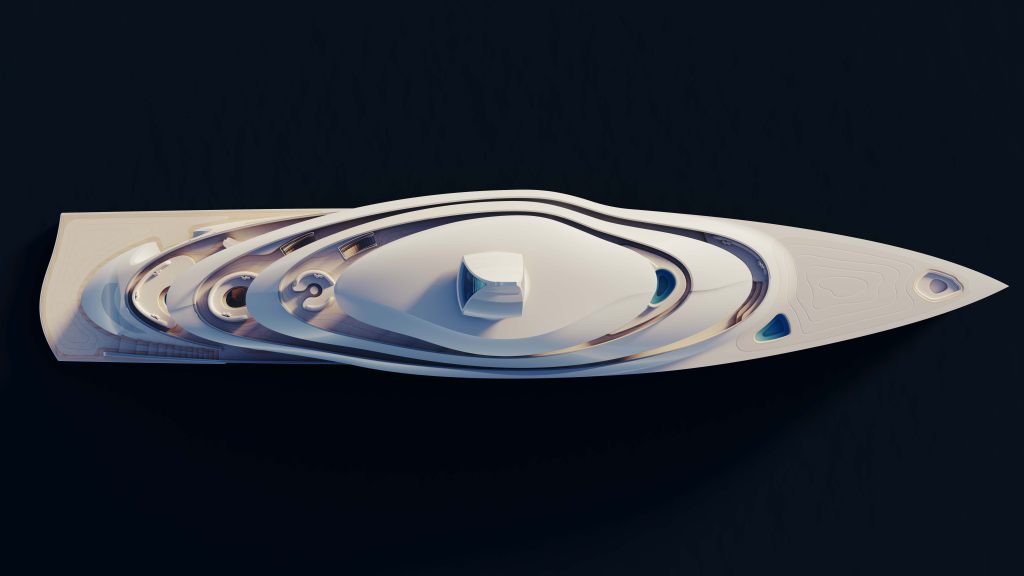

For more than a decade, its design and innovation teams have been unveiling concept designs based on solid Feadship knowledge and engineering to inspire future owners. The 2023 Monaco Yacht Show debuts Feadship’s twelfth cutting-edge Concept Design, a breath-taking 83-metre with significantly reduced energy needs. Flowing lines from Studio De Voogt reflect the concept’s namesake… Dunes, while the mast and stern add an air of mystery to the organic shapes of the superstructure. It’s what can’t be seen, however, that sets this concept at the forefront of sustainability.

Dunes takes a big leap toward Feadship’s goal of Net-Zero superyachts. Like a complex 3D puzzle, it combines features that reduce energy demand with technology that increases efficiency and eliminates emissions. Numerous factors, from shading windows to reduce cooling requirements to extra-capacity next-generation storage batteries, to abolishing teak decks, a new type of fuel cells, and even a radical propulsor, link in a beneficial design spiral. Alone, each element reduces environmental impact, but implemented together, Dunes will slash a superyacht’s environmental impact without diminishing the enjoyment of cruising. Assessed using the comprehensive YETI tooling, Dunes eliminates up to 95 per cent of the potential negative environmental factors associated with operating a superyacht compared to a yacht meeting today’s minimum environmental regulations.

A Concept begins with asking the right questions

Before we could begin drawing lines, we had to define the scope,” said designer Thijs Orth, who took the lead on this Concept. “From customer input, we thought the ‘envelope’ should contain six guest staterooms, plus a spa area, a beach club, an owner’s private deck and a pool. It would be a substantial hull.”

Then came a barrage of “what-ifs”. What if the engine room does not sit in the middle of the yacht? What if guest staterooms could have direct access to the beach club? What if we moved the bridge as on Concept Pure (2021)? What if the fuel cells don’t require hydrogen storage tanks? What if there is an entire multipurpose deck? What if we update the passive ventilation system of Concept Breathe (2010)?

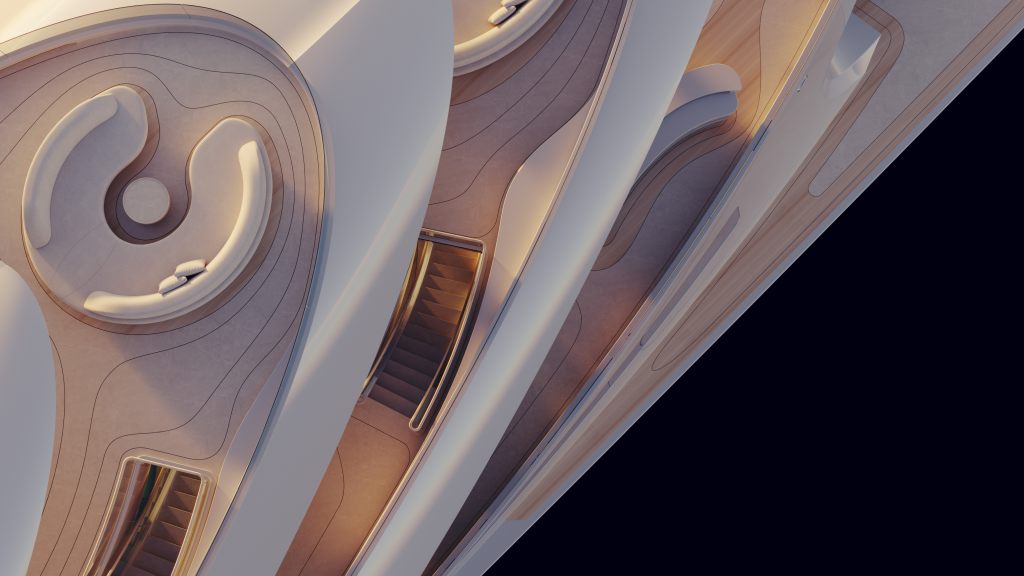

What if the superstructure is asymmetrical? What if the decks themselves could generate electricity? What if, indeed! These and other questions led to new solutions for old problems. The knock-on effects of just one change – moving the engine room from the most comfortable spot on a boat to areas forward — opened up the possibility of an entirely new layout where gracious lower deck guest suites link to a fantastic beach club, water sports platform, and the pool above.

This also eliminates large engine room air and exhaust trunks from compromising saloons or dictating stairway placement. Electric yachts do not need huge gearboxes, long shafts and propellors. Electricity-generating fuel cells, battery banks and the power management station can be decentralized and located virtually anywhere convenient to the crew. Speaking of convenient, a virtual helm station or command centre on the lower deck next to the crew quarters rather than several decks away where it compromises owner/guest space is feasible.

For aesthetic inspiration, Studio De Voogt focused on undulating waves, not of water, but of sand. Noticing how dunes are never fixed, their ripples and valleys appearing to shift with light and shadow, the designers explored ideas about line, flow, and adaptability. Dunes undulating curves emerged as a backdrop for the onboard lifestyle today’s owners desire with adaptable, multi-purpose spaces, endless views, and a mix of open-plan areas and cosy, intimate spaces. Surrounding guests with design inspired by nature allows them to relax even more once they step onboard.

While decks often get squeezed by indoor accommodation, gracious, shady walk-around decks are a main feature of this design. In addition to the feeling of being protected from the elements, they offer alternate circulation routes around the yacht as well as unexpected outdoor seating and entertaining areas. Freeing design from the belief that all shaded outdoor areas must be aft creates multiple destinations and places of privacy. An instantly recognizable feature of Dunes is that her asymmetrical superstructure has almost no straight lines. Spaces seem to drift from one to the other rather than march in stiff corridors. Staircases are circular or gently curved. So, too, are windows and doors of full-height glass. This much glass could create tremendous heat loads in sunny climates were it not for attention to overhangs. Seen from the sun, only little slivers of the full-height superstructure windows are visible for much of the day as the curves of the overhangs follow the contours of the glass. A calculation showed these handsome deck shoulders decrease heat building behind the glass by 60 per cent.

A broader look at sustainability

Sustainability is more than controlling exhaust emissions. With an international treaty prohibiting old-growth Burmese teak imports by all the world’s major yacht-building nations, and demand far outpacing the supply of suitable plantation-grown teak, the responsible position is to move on. Dunes is teak-free. Two new luxury decking systems being tested by Feadship combine for this concept.

Outside, the topsides shimmer with teak-free decks made of millions of tiny glass or stone chips sealed in a transparent aliphatic polyurethane resin. The resin surface can be sculpted in myriad shapes to show direction or amplify the impact of built-in features. The designers envisioned alfresco lounges appearing as islands on the decks and rendered them clad in beautiful, golden, maple wood – a sustainable teak lookalike. The long aft overhangs are uniquely supported by a stunning, single maple-clad column, uniting decorative sections of maple overhead with those below.

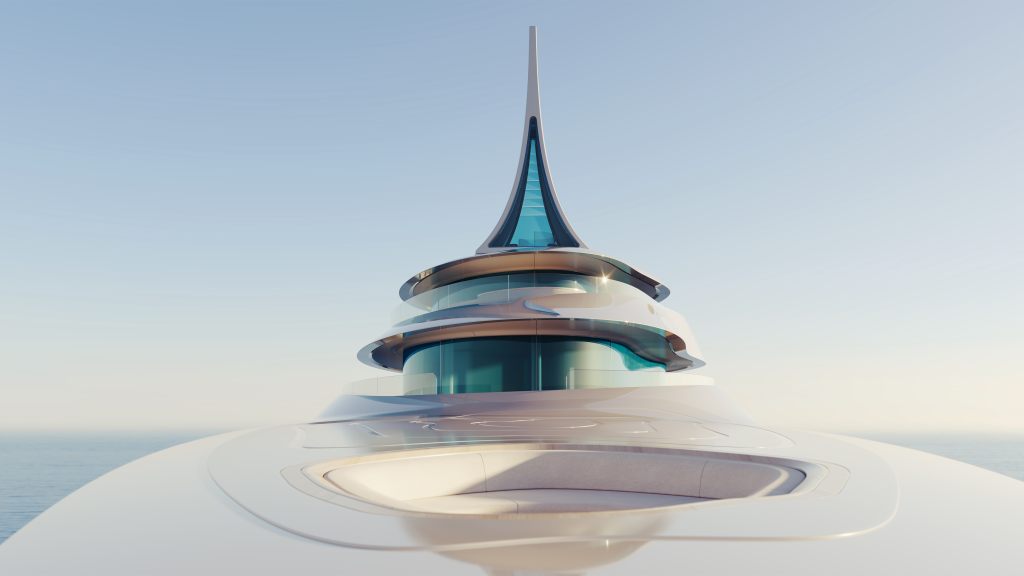

Notably, the uppermost Pavilion Deck structure is built of wood. While this is how early Feadships, and in fact, most steel-hulled vessels, were built in the days before aluminium, this choice is based not on a quirky juxtaposition with the past, but on science. Treated timber is a CO2-negative building material with a high natural insulating capacity. This benefit and the beauty of the material come without increasing its overall weight. The Pavilion Deck is an exciting concept. Surrounded by glass and separating a forward sun and Jacuzzi zone from an informal dining and conversation area aft, it can be outfitted for formal indoor dining or any number of purposes from night club to conference room. Circular stairs lead from this area to the yacht’s signature feature, its striking 10-metre mast. More than just arresting design, it has an important technical function.

Further reducing the amount of energy needed to cool the yacht, the mast is part of Studio De Voogt’s Cool Core Concept. Like a desert house, Dunes is divided into temperature zones. Sleeping quarters are cool (19-20 degrees), social areas are about 22-23 degrees, and the Pavilion estimate is 24-25 degrees. The Pavilion is cooled using air drawn up the central staircase from other parts of the ship as if by magic without the use of fans and ducts. It is not magic but simple physics that makes it work. The mast shape is a triangle of convex and concave foils. It sits on a large bearing ring that allows it to align with the direction of the wind. As the breeze crosses the mast, its shape generates a low-pressure zone on the leeside, naturally pulling the slightly over-pressurized cooled air from lower decks to this level. Together with the large overhangs, optimized recirculation, and increased insulation throughout, Feadship calculates that HVAC energy use is reduced by 35 per cent on an annual basis.

The wind, as they say, is free, and so is the electricity generated by a wind turbine or the sun. Feadship engineers devised a slim, two-blade vane that nearly disappears in the mast structure. Used only at anchor, this turbine can yield about 25 MWh per year. We imagine Dunes’s foredeck coated with a thin film solar panel. Called solar paint, this technology is in its infancy and its efficiency today is low. Currently, the effect is the proverbial drop in the ocean. But then again, why not collect it?

Putting a different spin on props

For the first time since screw-type propellers began to replace paddlewheels on steamships in the 1840s, there is something truly new in propulsion. Dunes introduces a breakthrough, high-efficiency electric propulsion system from ABB called ABB DynafinTM unveiled last May. In development and testing for ten years, the ABB Dynafin™ utilises revolving, vertical blades to mimic the thrust of a whale’s tail – one of the most efficient forms of thrust ever seen. The first prototype is estimated to be available in 2025, with hydrodynamic efficiency targeted to be up to 85 per cent, up from 65 per cent for current pod drives, or 55-60 per cent for typical propellors on shafts. An independent study of ABB Dynafin™ of a passenger vessel design equipped with different propulsion solutions has verified savings in propulsion energy consumption of up to 22 per cent compared to conventional shaft line configuration.

The ABB Dynafin™ propulsion will be driven by electricity generated from equally revolutionary solid oxide fuel cells that use green methanol as a reaction agent. Methanol can be converted to hydrogen in one step and does not require cryogenic storage. Green methanol (produced from non-fossil-fuel sources) is seen by Feadship as the best fuel option, due to the relatively high energy density and ease of storage. “Contrary to the common assumption that using methanol means more than two times the fuel storage volume, on Dunes, we have so many power savings that we actually need less storage volume compared to a regular diesel fuel yacht,” said Senior Specialist Bram Jongepier.

Not content to just address the operation of the finished product, Feadship is making a quantum sustainability leap at the beginning of the construction process by shifting to “low impact” steel and aluminium for hulls and superstructures, which make up more than half of the build CO2 impact. Using a high scrap content and sustainable energy in the manufacturing process, these certified metals can be produced with 50-70 per cent less CO2 emissions. Feadship has already integrated low-impact aluminium on one vessel in build and made it standard material for all future new builds.

Feadship Concept Designs are a true joint effort. As so many things within Feadship, this is an extensive team effort, in which colleagues from Studio de Voogt and the Knowledge & Innovation department (designers, specialists, naval architects, modelers, researchers, 26 in total) all combine their specialty. Also, being part of the Feadship group of companies, we are privileged to have direct access to the wealth of knowledge and experience that is contained within the 2,500 colleagues from Naval Architecture and Engineering within De Voogt Naval Architects, all the engineers and craftsmen from the yards and their daughter companies, and Feadship Refit & Services. Feadship can only achieve this level of quality in its concept designs due to the solid support, collaboration, and critical opinion of every person within Feadship.